Refuse-Derived Fuel (RDF)

Refuse-Derived Fuel (RDF)

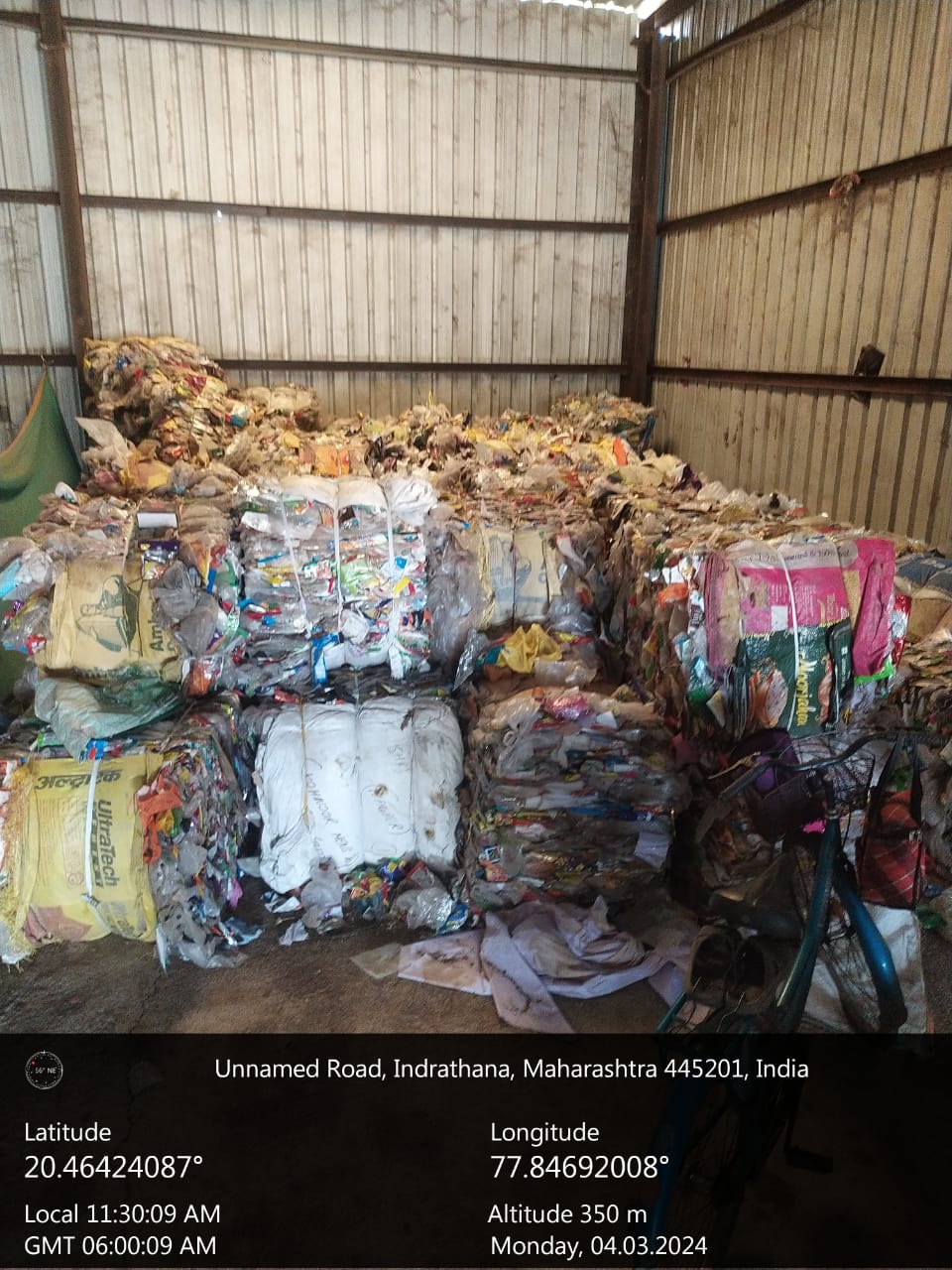

Aarya Waste Innovations play a crucial role in transforming waste into energy by producing and supplying high-quality Refuse-Derived Fuel (RDF). Our operations are aligned with national goals of landfill reduction, sustainable waste management and promoting alternative fuels for industries.

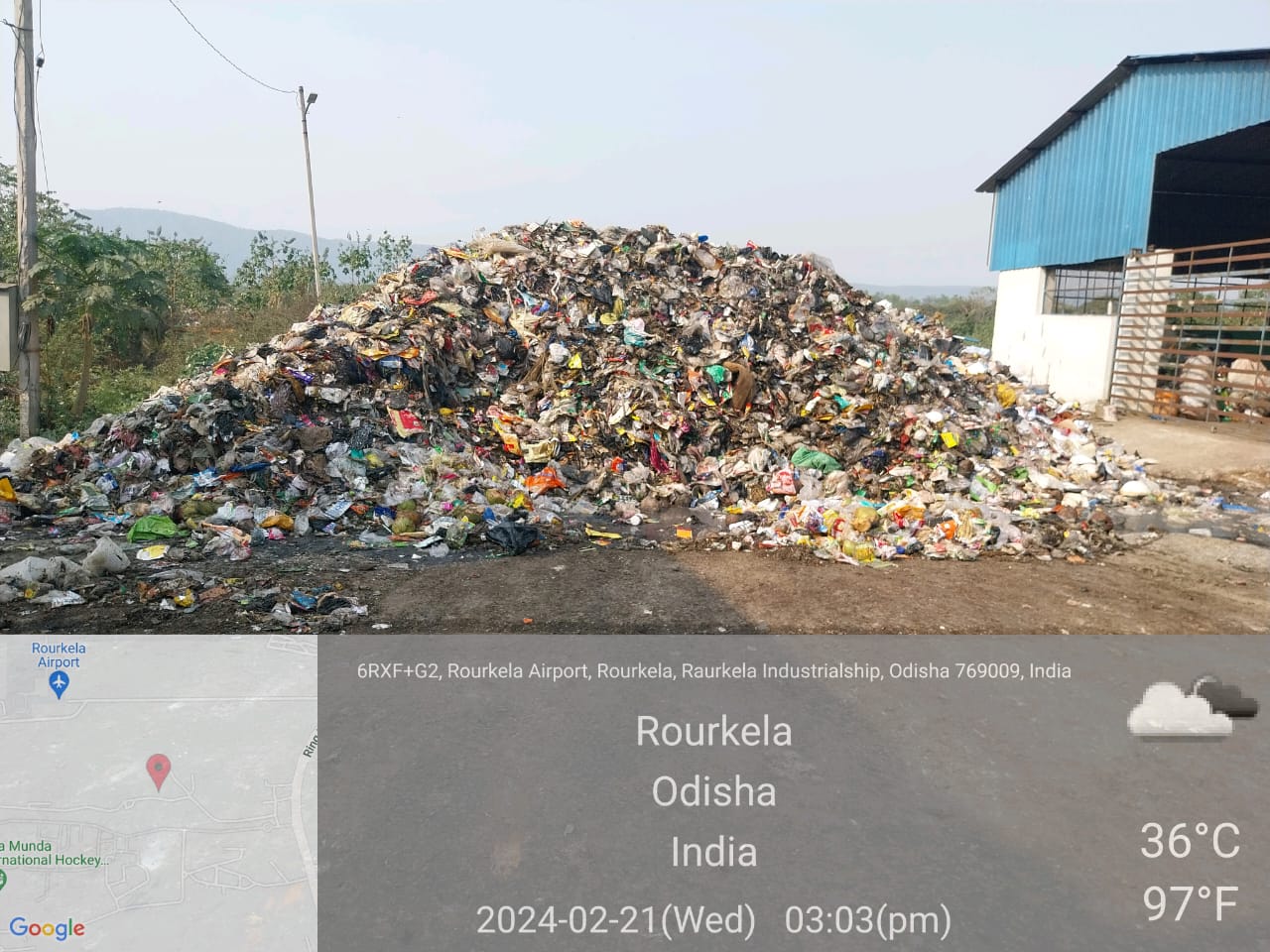

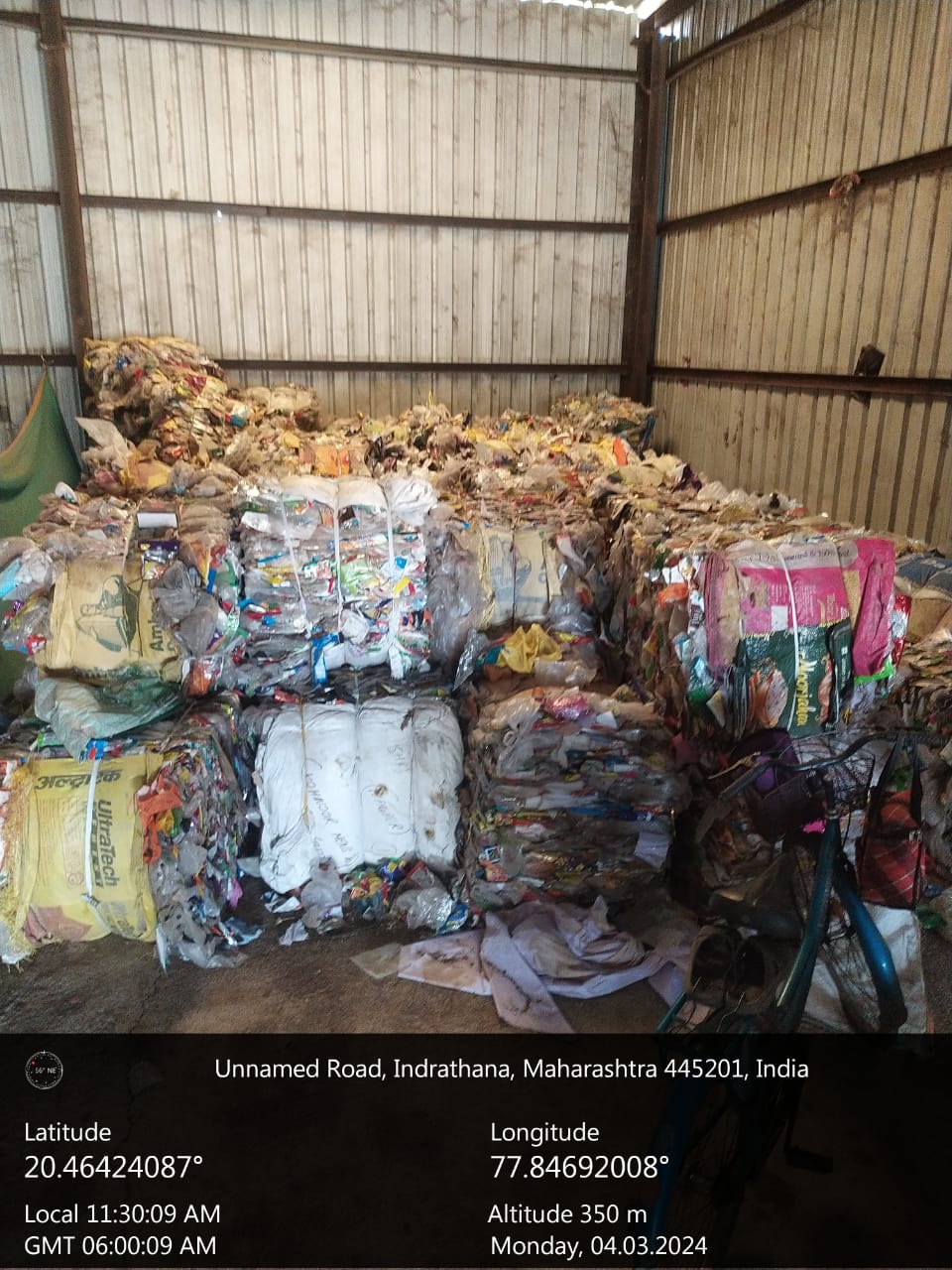

We actively work with municipal corporations and urban local bodies to clear legacy waste from landfills, ensuring cleaner cities and reclaimed land. This waste is processed into RDF, which we supply to cement industries and other co-processing units based on their specific calorific and material requirements.

With a robust supply chain across multiple locations in India, we ensure timely and efficient delivery of RDF that meets quality benchmarks. Our services not only support the circular economy but also help industries reduce their dependency on fossil fuels.

Step-by-Step RDF Process Flow

Nation-Wide Sourcing Networks

Collection of waste through ULB’s, Processing Sites, Landfill sites & Transferring Points.

Transportation to Disposal Facilities

Either to co-processing sites or disposal Industries Authorized by Respective Pollution Control Board.

Compliance and Certifications

Regulatory Proficiency with Real Time Tracking & Reporting Capabilities.

- Calorific Value (typically 2,500–4,000 kcal/kg)

- Moisture Content

- Ash Content

- Chlorine & Sulphur Levels

Trusted Partners